Visual Paradigm Desktop |

Visual Paradigm Desktop |  Visual Paradigm Online

Visual Paradigm OnlineWhen someone talks about warehouse automation, they often think of robots, scanners, and smart shelves. But behind every smart system is a clear structure—something that defines how components interact and work together.

That’s where AI-powered modeling software steps in. Instead of manually drawing relationships or guessing at package hierarchies, users can describe their system and get a well-organized, logical package diagram built instantly.

This isn’t just about visuals. It’s about understanding how the system parts fit together, from product tracking to shipping operations. The result is a clear, structured view that supports better decision-making.

Let’s follow a real user through their experience using AI-powered modeling software to design a warehouse automation system.

The user was a logistics project lead working on a new warehouse automation initiative. Their main goal was to visualize how different system components—like inventory tracking, robotic equipment, and user interfaces—would work together.

They didn’t have time to manually create a package diagram or spend hours organizing packages and relationships. What they needed was a clear, structured breakdown that reflected real-world operations.

The user started by asking:

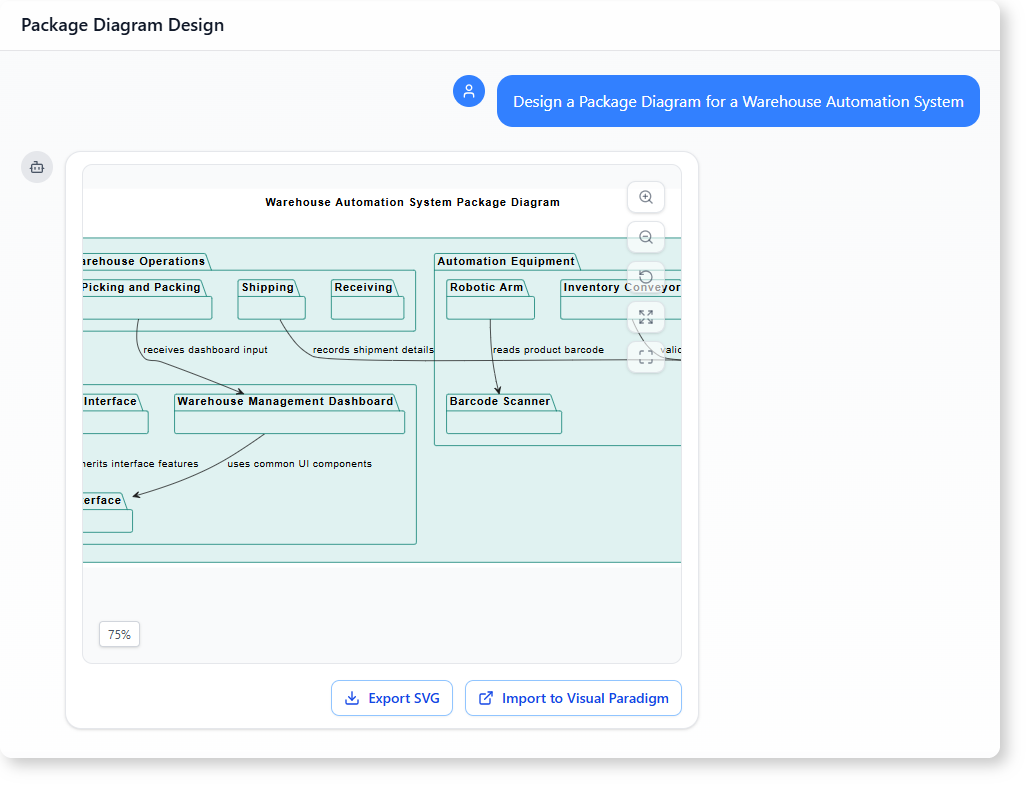

“Design a Package Diagram for a Warehouse Automation System.”

The AI responded by generating a hierarchical package diagram that clearly defines the core subsystems:

Each of these packages had internal structure, showing how specific functions like product tracking, robotic arms, and movement logs fit into the overall system.

The diagram used a top-to-bottom layout, making it easy to follow the flow from input to operations to data storage. Key relationships were added to show dependencies—such as how product tracking accesses the product database or how robotic arms read barcodes.

This wasn’t just a visual—it was a logical structure that reflected how the system actually functions.

After reviewing the diagram, the user asked a follow-up:

“Provide a report describing how the package structure contributes to system clarity.”

The AI generated a detailed report that explained:

This report turned the diagram into a living document—something that could be shared with stakeholders, used in planning meetings, or handed over to developers.

Using AI-powered modeling software isn’t about replacing human judgment—it’s about freeing up time to focus on what really matters: understanding the system.

The package structure in the warehouse automation system shows how:

This level of clarity helps teams avoid duplication, reduces errors, and improves communication.

A tool that can interpret natural language and produce both a structured diagram and a meaningful report is a powerful asset in system design.

Traditional modeling requires diagrams to be drawn by hand or in software with strict formatting rules. This can lead to:

An AI-powered modeling tool eliminates these issues by:

This is especially helpful in complex domains like logistics or manufacturing, where systems involve many moving parts.

A package diagram helps separate the system into manageable, logically grouped parts. This makes it easier to assign teams, understand responsibilities, and visualize how components interact without getting lost in details.

Yes. With advanced language processing, the AI can interpret prompts like “Design a warehouse automation system” and build accurate, context-aware diagrams based on real-world logic.

It reveals hidden patterns in how components relate to each other. By showing which parts depend on others, it helps prevent design flaws and ensures system integrity.

Absolutely. The report explains not just what the diagram shows, but why it matters—how structure supports clarity, scalability, and team coordination.

Give our AI-powered modeling software a try at Visual Paradigm’s AI Chatbot today!